|

Changzhou Mingjie Building Material Equipment Manufacturing Company

|

AAC Pouring Ferry Car Concrete Mixing Plant / AAC Block Machinery

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

AAC pouring ferry Concrete Mixing Plant / AAC Block Machinery

<span style="font-size:14px"

AAC pouring ferry Concrete Mixing Plant / AAC Block Machinery

Pouring ferry car

1. Function:

Pouring conveyor cars are indispensable conveyance devices in the process of manufacturing aerated concrete products. They serve to carry the cut concrete blocks to the autoclave to be steam cured, the moulds that are waiting for pouring to the pouring line and the steam-cured concrete blocks to the product line.

2. Major technical specifications

a) Maximum overall dimensions:

4560 mm (length) × 2500 mm (width) × 555 mm (height)

b) Mass: 3258 kg

c) Maximum load capacity: 7.5 tons

d) Speed reducer of the main drive: WHX12-40-II

e) Motor:

Type: YD90L-4/2

Power: N = 1.3/1.8 kW

Speed: n = 1430/2850 rounds per minute (rpm)

f) Running speed: V1 = 8.6 m/min

3. Structure

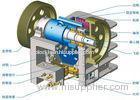

A conveyor car is made up of two systems: the frame and the drive

a) Frame: The frame of the conveyor car is a structure of rectangular steel tubes. It is made of welded rectangular steel tubes and steel angles. They are rigid enough to support the maximum load of the machine. On its top is an anti-slip checkered steel plate and rails for positioning autoclave cars or moulds.

b)The drive system includes the main drive unit and the driven drive unit. The main drive unit includes an electric motor, a speed reducer, a drive shaft, a coupling and wheels. Its operation is controlled by the electric cabinet.

4. Operation:

When the electric cabinet begins to supply power to the electric motor, the main drive unit puts the pouring conveyor car in operation so that the concrete blocks cut by the main machine are delivered to the autoclave line and the finished products coming out of the autoclave are delivered to the product line.

5. Adjustment and trial operation

a) Adjustment:

i.The wheels should be able to rotate freely without jamming.

ii.When the conveyor car is running on the rails, its four wheels should be leveled on the same surface with a tolerance not bigger than 2 mm. If the deviation is bigger than the tolerance, adjust by means of the adjusting screws on top of the wheels.

b)Trial operation

i.Trial-run the conveyor car without any load first. Press the button on the electric cabinet to start the motor. The pouring conveyor car should be able to run to and fro smoothly and stably for half an hour without any abnormal noise from the speed reducer and without any jamming of the wheels.

6. Maintenance

a) Daily care:

Remove all dust and dirt after production is finished at the end of each shift. The wheels should be lubricated every day before production begins.

b) Maintenance:

i.Do a minor repair monthly, in particular the wheels and all components in the drive system. Replace any components found to be damaged.

ii.Do a medium repair every six months. In addition to the items to be checked during the minor repair, check and test the electrics and wirings. Lubricate the speed reducer.

iii.Do an overhaul yearly. Disassemble and clean all the components in the drive system. Replace any parts that are found to be worn out. Lubricate the speed reducer.

7. Safety

a) Check carefully the electrics and wirings every shift before production begins. Switch off the power after production is finished.

b) While the pouring conveyor car is running, do not allow anybody to stand in its tank or within the scope of its operation.